Quick Summary:

This blog covers the two types of communicating methods Trapezoidal & Sinusoidal BLDC motor control. Go through both of them along with the advantages and disadvantages of each method.

I hope this piece of content proves to meet your expectations. Looking for your feedback in comments.

Introduction

With the Brushless motor technology, you can get high reliability along with efficiency in your applications; that too at a lower cost as compared to the brushed motors. Brushless DC motor and Permanent magnet synchronous motor(PMSM) both consist brushless characteristics.Both motors are synchronous machines.There’s very small difference between them.The difference is the shape of their back emf.BLDC and PMSM motor has respectively trapezoidal and sinusoidal back emf.In reality motor can not produce exactly trapezoidal back emf but it is more like to sinusoidal. So sometimes type of motor doesn’t matter but the commutation(control) method matters more than that.

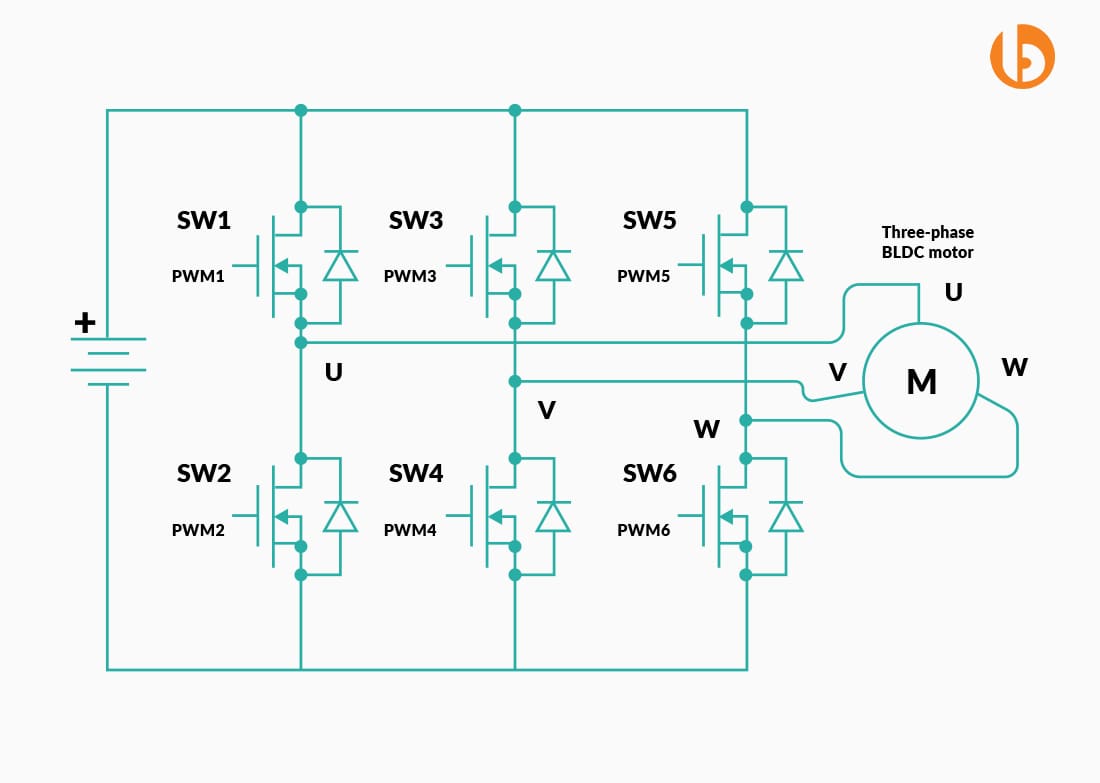

It is necessary to have stator winding currents have the same shape as its back EMF to get maximum efficiency.The drive current is given to three phase motor from the inverter depending upon PWM applied to it.PWM is generated using the controller.Stator winding current is changing according to the rotor position.Rotor position is acquired by the HALL sensor,QEP encoder or any other mathematical methods.The different method is used for the drive current generation depending upon the back EMF of the motor.

Here is a figure of a Brushless Motor Control(BLDC/PMSM).

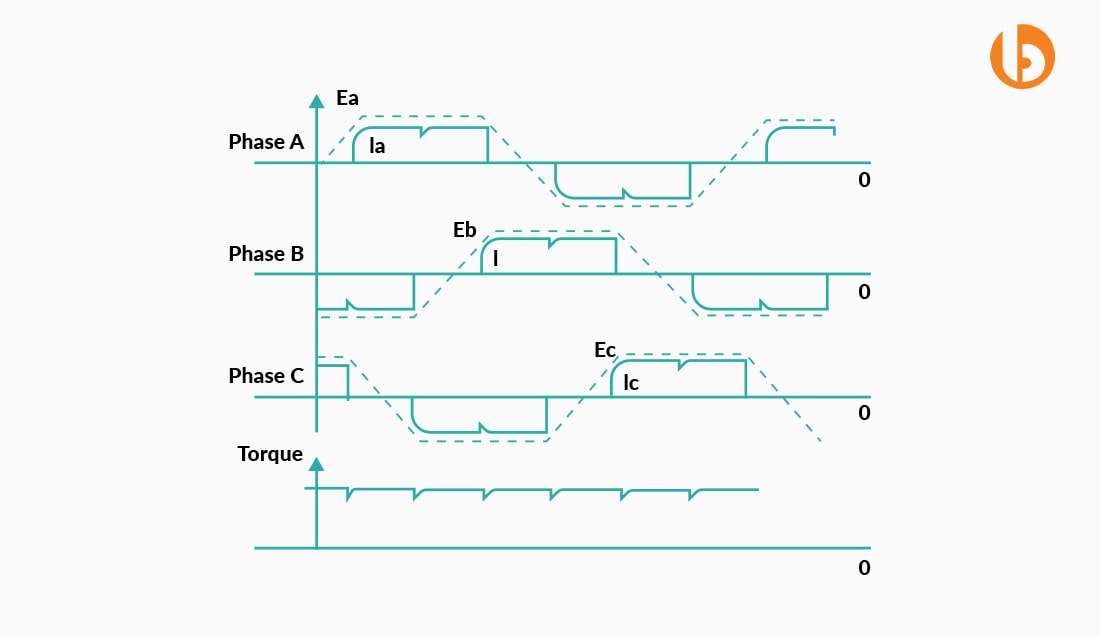

Trapezoidal Control

Trapezoidal commutation method defines the shape of back EMF and drive current waveform. To get the optimum performance from the motor, the drive current should match the back Electro Motive Force waveform. As back EMF of BLDC motor is in trapezoidal shape it should be driven with trapezoidal current to get best performance. Trapezoidal commutation is also known as “Six Step Commutation” because there are total six steps of drive current used to complete one revolution of rotor. In trapezoidal control at a time only two phase are active. This method has simple control algorithm but the torque ripple exist in the motor at every commutation(60 Degree).

Advantages

- Control Algorithm is simple

- Only two phase is needed to active at time

- Less switching losses

Disadvantages

- Torque ripple at every commutation

- Torque produced is less

- Acoustic and electric noise

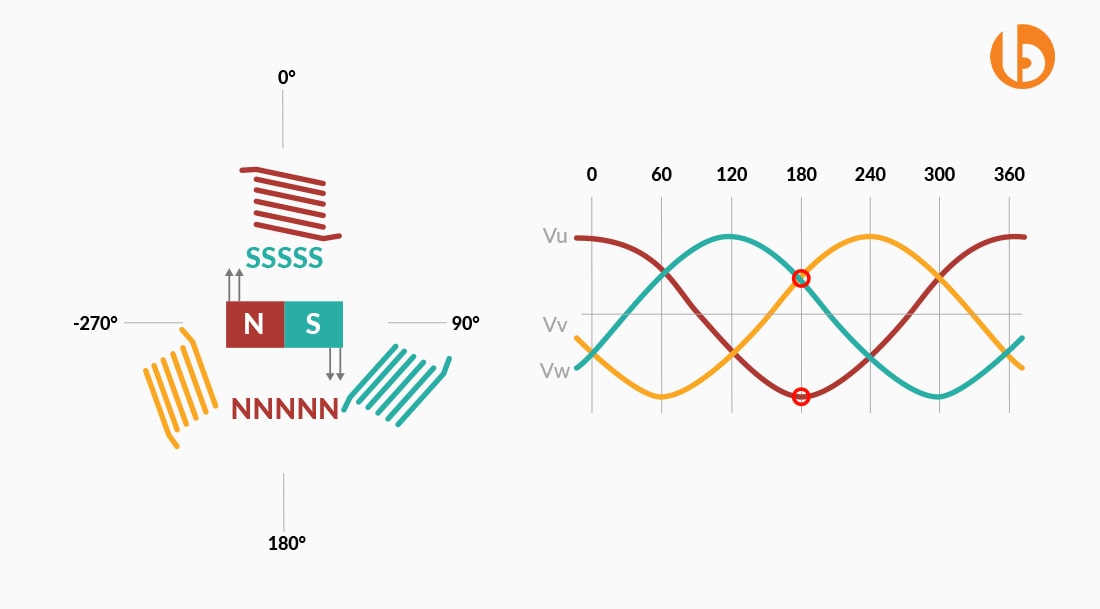

Sinusoidal Control

The Sinusoidal commutation is used in Permanent Magnet Synchronous Motors because the PMSM motor has the sinusoidal back EMF. Although theoretically, the back Electro Magnetic Force waveform of a BLDC motor is trapezoidal, but the inductance in the motor smoothens it into a sinusoidal shape. This is why BLDC motor can use either of the two- trapezoidal or sinusoidal commutation methods.

As its name suggests the shape of the back EMF and drive current is sinusoidal in this method. Sinusoidal control eliminates the torque ripple and give smooth motion. The basic principle of sinusoidal commutation is to provide sinusoidal current which vary according to rotor position. The current are phase shifted by 120 Degrees. Sinusoidal control is achieved by using Field Oriented Control Algorithm. The basic principle of this algorithm is that the maximum torque is produced when rotor and stator magnetic field are orthogonal to each other. So sinusoidal current varies according to rotor position to get maximum torque and smooth motion.

Advantages

- No torque ripple in commutation

- Smooth motion

- Maximum Torque is produced

Disadvantages

- Possible to have three phase on same time

- Higher Switching losses

- Control Algorithms are complex and mathematically intensive

Practically BLDC and PMSM motor can run from any two methods because as said earlier we are not getting exactly trapezoidal back EMF but it somewhat looks like sinusoidal.

Although sinusoidal control algorithms are complex to implement,to get maximum torque and smooth motion in applications sinusoidal control should be used.In applications where less torque is not an issue,driving the motor with simple control algorithm with trapezoidal control is a better idea.

Conclusion

WIth this we conclude the blog discussion. Hoping that we could enlighten you on the topic. If you are confused between the two or have a thing in mind, our expert developers can help you decide the best for your project or idea. Contact Bacancy Systems and introduce yourself to amazingly modern solutions.

Frequently Asked Questions (FAQs)

Brushless DC motors are used in varied appliances such as ACs, washing machines, consumer electronics, etc.

On an average, the lifetime of a brushed motor is about 1000 to 3000 hours whereas, of a brushless motor is 10000 hours.

Brushless motors are not waterproof, but they are water-resistant.

Get in touch

Scale up your remote team and execute projects on time